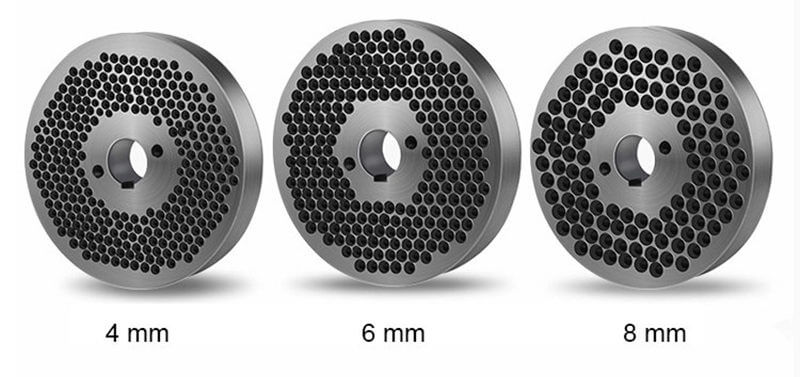

But this is not always the case. In some applications, spending more time and effort may help the drill bit meet quality standards in one operation. Alternatively, it can be determined that the quality of the drilling affects its ability to accept high-quality secondary processing. For example, if drilling at an excessively high speed, heat may cause the material to work hard, greatly reducing the lifespan of the tap and even making the material too hard to be tapped.

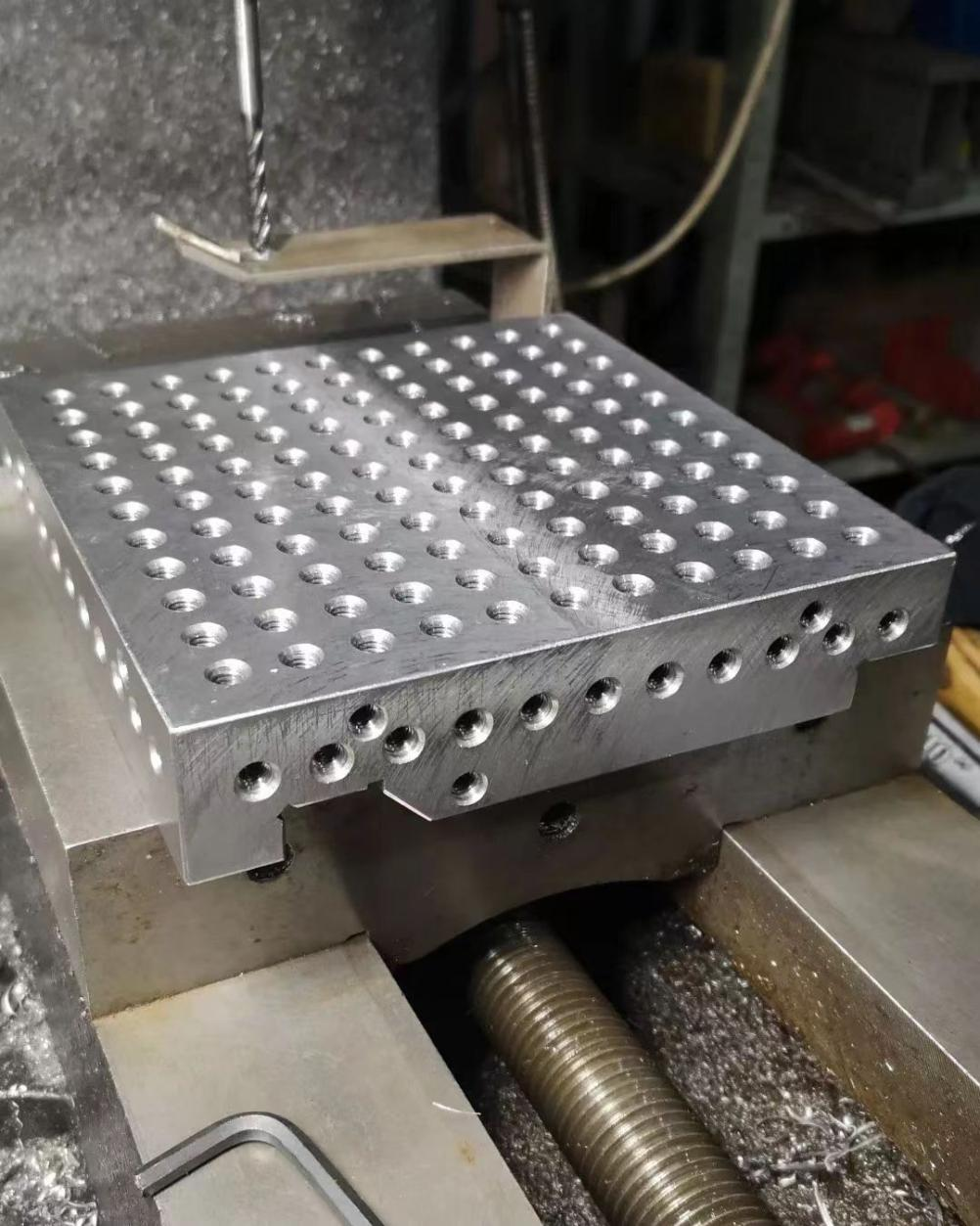

If a hard alloy drill bit drills 2 or 200 holes, it may be different; If it is 200, the quality focus may mainly be on the speed (efficiency) of completing the work; If this job only requires 2 holes, spending more time and effort during the drilling process, or using specially designed tools to drill and ream holes in one operation, can produce holes that meet quality specifications without additional processes.

Does 2 meet the requirements for hole machining.

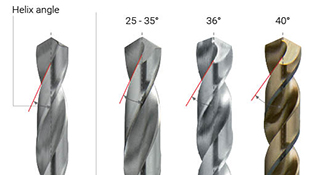

Hard alloy drill bits are actually applied in many fields, but many technologies are also overlooked. The design of spiral angles is also very particular, such as low spiral angles or straight groove drill bits, which are very suitable for short chip materials such as cast iron and ductile iron. For example, a spiral angle of 20-30 degree is conducive to universal drilling in various hard materials, as this angle helps to remove chips.

Some new coatings are combined with higher speeds to remove materials and produce pores with good smoothness. These coatings need to be able to withstand the heat generated by high-speed motion.